3D localisation and visualisation of cracks

Microtomography enables the non-destructive detection and 3D visualization of…

Home » Articles and News » Why choose X-ray tomography or microCT?

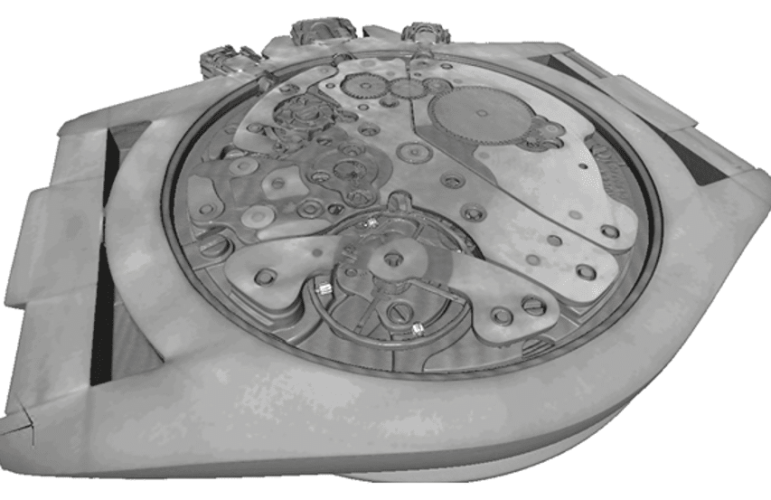

X-ray tomography is now a reference method for non-destructive three-dimensional imaging.

Its principle is based on capturing a large number of X-ray images from different angles, which are then combined digitally to reconstruct the internal structure of an object.

Tomography, which has become essential in various fields such as material research, component development, or industrial quality control, offers a detailed visualization of both the external geometry and internal characteristics of the parts as well as the microstructure of any type of material.

As an independent laboratory, Novitom allows organizations to access synchrotron microtomography and nanotomography:

Microtomography enables the non-destructive detection and 3D visualization of…

A recent study conducted by Xploraytion, Novitom, Merck and…

Why perform microCT during tensile/compression tests? The use of…