3D localisation and visualisation of cracks

Microtomography enables the non-destructive detection and 3D visualization of…

Home » Our services » Multi-scale tomography » 3D characterisation of cracks

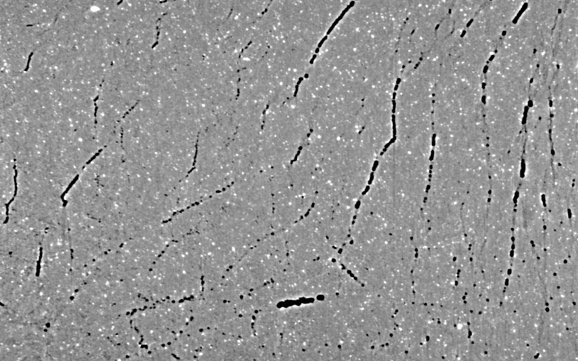

Microcracks, crazing, fatigue cracks, shrinkage cracks, or drying cracks… The presence and evolution of cracks determine the mechanical strength, lifespan, functionality, and safety of your products.

If left unchecked, they can lead to premature failures, reduce fatigue resistance, or compromise the integrity of a structure. Using X-ray tomography, we offer a non-destructive, multi-scale 3D analysis to detect, visualize, and quantify internal cracks, from microns to centimeters, and monitor their evolution under real-world conditions.

Dimensions: proportion of the volume affected, overall and local extent

Crack geometry: length, opening, height, slenderness, orientation

Location: position of cracks within the component, proximity to inclusions or interfaces

Connectivity and propagation: crack network, branching, coalescence, tortuosity

Dynamic evolution: in-situ monitoring of crack propagation under mechanical (tension, compression, fatigue), thermal, or environmental stresses

Additive manufacturing – 3D printed alloys and polymers

Metallurgy, Foundry, and Heat Treatment

Welding, brazing, and assembly

Composite materials – fibers + polymer or ceramic matrices

Ceramics, glasses, and refractory materials

Polymers and elastomers

Geomaterials and natural samples

Biomedical materials and tissues

Pharmaceuticals – solid dosage forms

Microtomography enables the non-destructive detection and 3D visualization of…

A recent study conducted by Xploraytion, Novitom, Merck, and…

Why perform microCT during tensile/compression tests? The use of…

A recent study conducted by Xploraytion, Novitom, Merck, and…

Microtomography enables the non-destructive detection and 3D visualization of…

For measurements on R&D samples as well as finished products:

For visual renderings and quantitative results tailored to your needs:

Over 20 years of experience in advanced tomography and interpretation of complex results

Precise quantitative data, non-destructive and multi-scale inspections tailored to your application

Solutions tailored to your constraints, detailed reports and 3D visuals to facilitate decision-making