Tracking the evolution of materials microstructure : in situ mechanical testing with Novi CT Rig

Why perform microCT during tensile/compression tests? The use of…

Study the evolution of the microstructure of materials with NOVI CT Rig using microCT or diffraction.

No cable on the rotating platform!

The testing device can be integrated into synchrotron instruments and laboratory equipment.

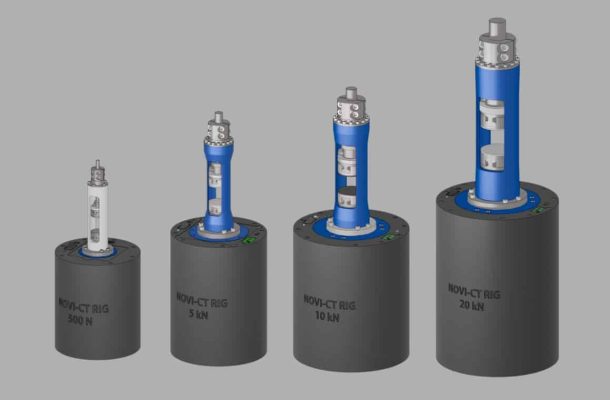

Novitom designs and develops a range of tensile/compression devices compatible with load cells from 500 N to 20 kN.

The NOVI CT Rig range is designed to optimise microtomography image quality while ensuring ergonomics and practicality for the user.

NOVI CT Rig instruments are designed to integrate easily into tomography, microtomography and diffraction equipment, both in terms of space requirements and wireless control.

Microtomography images allow the evolution of the microstructure of materials to be observed and characterised, in particular deformation fields and local damage, as a function of the mechanical stresses applied.

Multiple load capacities 500 to 20 000 N

Interchangeable force cells

Calibration ki

Several types of jaws

Several types of chambers

Customised adapter plate for the tomograph

Wireless power supply and communication

System for adjusting to sample height without affecting stroke length

Ultra-fast sample mounting in open chamber

Quick chamber assembly/disassembly

Ultra-fast machine mounting on battery box

Wireless communication with the machine

Battery power supply: 2 battery sizes (8 hours or 24 hours)

Control software installed on the tomography station

Press capacity | 500 N | 5 kN | 10 kN | 20 kN |

Tensile jaws | Dog-bone type* | Dog-bone type* | Dog-bone type* | Dog-bone type* |

Compression patens diameter | 15 mm* | 30 mm* | 40 mm* | 45 mm* |

Open sample chamber (external diameter) | ⌀ext = 30 mm | ⌀ext = 35 mm | ⌀ext = 48 mm | ⌀ext = 64 mm |

Actuator stroke (jaw-to-jaw) | 20 mm | 20 mm | 20 mm | 20 mm |

Loadcell linearity | 0.2% full range | 0.2% full range | 0.2% full range | 0.2% full range |

Displacement sensor | Linear absolute encoder (resolution 1 nm) | Linear absolute encoder (resolution 1 nm) | Linear absolute encoder (resolution 1 nm) | Linear absolute encoder (resolution 1 nm) |

*customizable upon request

+33 7 49 39 91 42

andrea.ciuffini@novitom.com

Novitom’s expertise lies in taking into account the image quality expected in microtomography, whether in synchrotron installations or laboratories.

The quality of microtomography data determines the accurate interpretation of readings, measurements and analyses made on these images during tensile/compression tests. This expertise is reflected in the technical choices made in the design of the NOVI CT Rig range and its associated control system.

Novitom supports its customers with NOVI CT Rig by providing advice on sample geometry and acquisition parameters to optimise the quality of the data acquired.

Novitom also provides a comprehensive service in mechanical testing and 4D process monitoring, using the NOVI CT Rig range to meet its customers’ needs for in-situ microstructure analysis using X-ray microtomography, diffraction.

Why perform microCT during tensile/compression tests? The use of…

All types of materials: polymers, composites, ceramics, metals, foams, biomaterials.

For tensile testing, Novitom offers a tensile test specimen geometry optimised for microtomography measurements.

For compression testing, the diameter of the samples can be up to 40 mm after deformation.