Tracking the evolution of materials microstructure : in situ mechanical testing with Novi CT Rig

Why perform microCT during tensile/compression tests? The use of…

Home » Materials and processes » Metals and alloys

Our advanced analysis laboratory supports you in understanding and controlling your materials, combining cutting-edge technologies, industrial experience, and scientific expertise.

As a trusted partner, we are committed to helping you solve your challenges, secure your processes, and accelerate your development.

From rapid material testing to in-depth investigation, we provide clear and actionable results, directly focused on your performance, reliability, and innovation objectives.

We help you understand and control your materials through a wide range of services:

We put our scientific and industrial expertise at your side to transform your ideas into concrete solutions and your materials into true performance drivers.

Our R&D support services:

Why perform microCT during tensile/compression tests? The use of…

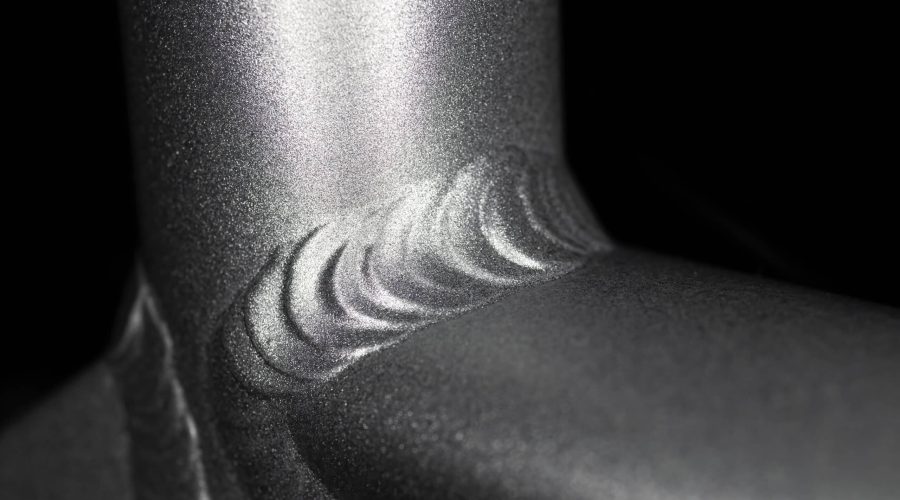

High-resolution, high-energy X-ray tomography provides non-destructive access to the…

Microtomography enables the non-destructive detection and 3D visualization of…

We analyse all types of materials, including powders, test specimens, metal parts, and composites.

Analyses carried out on state-of-the-art equipment by a team of experts.

An approach tailored to your constraints, with a technical contact person who supports you from start to finish.

Actionable results thanks to detailed reports and 3D visuals that facilitate decision-making.