Tracking the evolution of materials microstructure : in situ mechanical testing with Novi CT Rig

Why perform microCT during tensile/compression tests? The use of…

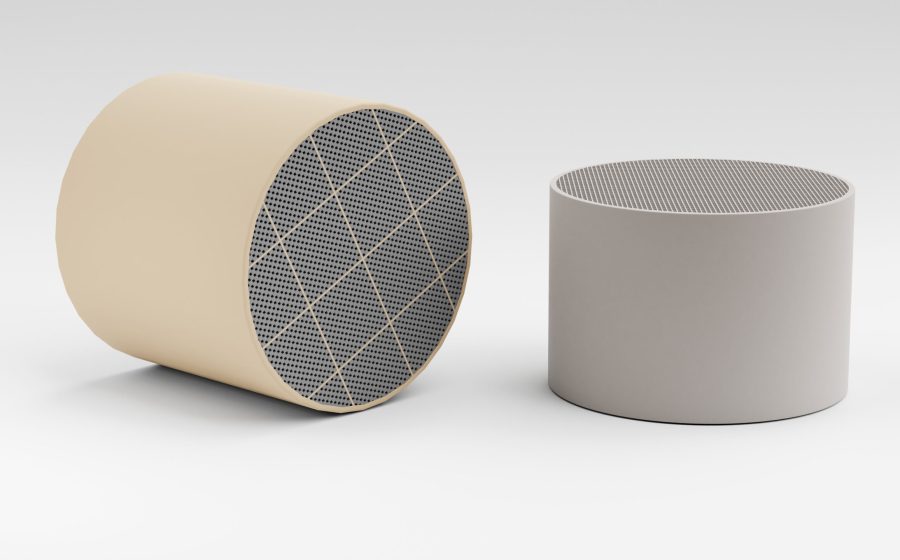

Home » Materials and processes » Ceramics and glass

Our analysis laboratory combines cutting-edge techniques and recognised expertise to meet your glass and ceramic characterisation needs: routine testing, process validation or advanced investigation for R&D.

As a trusted partner, we help you solve your problems: controlling critical defects (porosity, cracks, inclusions), characterising microstructures, evaluating the effects of ageing and optimising your processes to improve reliability in service.

We help you understand and master your technical ceramics through a wide range of services:

Why perform microCT during tensile/compression tests? The use of…

Microtomography enables the non-destructive detection and 3D visualization of…

We work with a wide range of glass and ceramic materials, in the form of powders, solid samples, thin films or complex assemblies:

Analyses carried out on state-of-the-art equipment by a team of experts.

An approach tailored to your constraints, with a technical contact person who supports you from start to finish.

Actionable results thanks to detailed reports and 3D visuals that facilitate decision-making.