Revealing the hidden structure of tablets with synchrotron X-rays

A recent study conducted by Xploraytion, Novitom, Merck, and…

Home » Our services » Multi-scale tomography » Porosity analyses

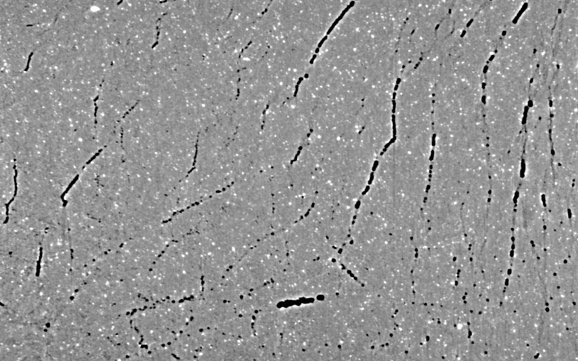

Bubbles, microcavities, interconnected pores… Porosity directly affects the mechanical strength, thermal resistance and durability of a material. Poorly controlled porosity can reduce strength, cause premature failure or impair the functionality of a product.

Using X-ray tomography and microtomography, NOVITOM offers you a non-destructive, multi-scale 3D analysis of sub-micrometric pores to large porosities.

Volume porosity: proportion of total volume occupied by pores.

Size and shape distribution: equivalent diameter, average size, sphericity, shape factor, orientation, Feret diameter.

Spatial location: position of porosities in the part or structure.

Connectivity: distinction between open and closed pores, size of interconnected porous network, local thickness, tortuosity.

Dynamic evolution of porosity under mechanical, thermal or chemical stresses

Foam cells: cell volume, cell density, size distribution

Complete, non-destructive 3D view: detects and measures all porosities, open or closed, without sample preparation bias

Multi-scale accuracy: from millimetres to sub-microns, for massive samples or fine microstructures

Reliable and comprehensive quantification: pore volume, size, shape, distribution and connectivity, without sampling bias

Data usable for modelling and AI algorithms: generation of comprehensive datasets to correlate microstructure and performance

Observation under real conditions: in situ monitoring of porosity evolution under mechanical, thermal or chemical stresses

A recent study conducted by Xploraytion, Novitom, Merck, and…

A recent study conducted by Xploraytion, Novitom, Merck, and…

For measuring R&D samples and finished products:

Analyses carried out on state-of-the-art equipment by a team of experts.

An approach tailored to your constraints, with a technical contact person who supports you from start to finish.

Actionable results thanks to detailed reports and 3D visuals that facilitate decision-making.